Ai-enhanced robotics in manufacturing allow you to achieve smarter and more adaptable production processes. These robots learn from their experiences, improve performance, and quickly adapt to new tasks or components, reducing downtime and increasing efficiency. They work safely alongside humans and help maintain high-quality standards through precise inspection and predictive maintenance. If you want to discover how this technology is revolutionizing industries and what benefits it can bring, there’s more to explore ahead.

Key Takeaways

- AI-enabled robots analyze surroundings and make real-time decisions to improve manufacturing efficiency and flexibility.

- Robots learn from experience, adapting instantly to new components and variations, reducing downtime.

- AI-driven quality control systems detect defects and anomalies with high accuracy, ensuring consistent product quality.

- Cobots equipped with AI collaborate safely with humans, interpreting gestures and speech for seamless workflow integration.

- AI-enhanced robotics streamline operations, enable rapid response to market changes, and strengthen manufacturing competitiveness.

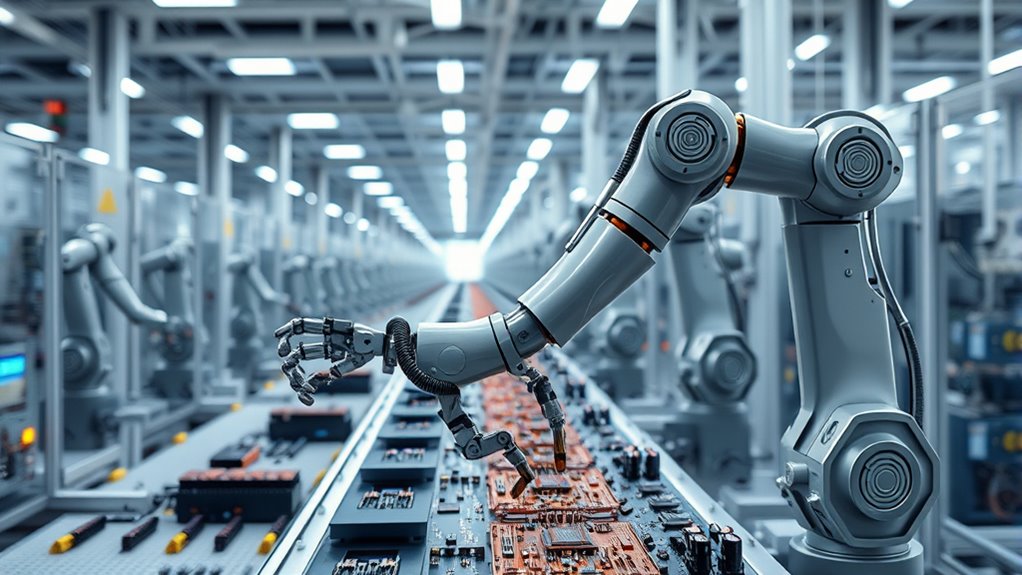

Artificial intelligence is transforming manufacturing by making robots smarter and more adaptable. With this shift, robotic automation no longer just involves simple, repetitive tasks; instead, it leverages AI integration to enable machines to perform complex actions with greater precision and flexibility. You’ll notice that AI-powered robots can analyze their surroundings, make real-time decisions, and adjust their behavior accordingly, which markedly enhances productivity and safety on the shop floor. This evolution means you can rely less on manual oversight and more on intelligent systems that optimize workflows continuously.

AI integration in robotic automation allows these machines to learn from their experiences, improving their performance over time without needing constant reprogramming. For example, if a robot encounters a new type of component or a slight variation in a task, it can adapt on the spot, reducing downtime and minimizing errors. This self-improving capability is crucial for industries where product variations are frequent, or production schedules change rapidly. As a result, your manufacturing process becomes more resilient and responsive to market demands, giving you a competitive edge.

Moreover, AI-driven robotic automation enhances quality control. Robots equipped with AI can scan parts for defects, measure dimensions with high precision, and identify anomalies that might escape human eyes. This not only ensures consistent product quality but also reduces waste and rework costs. AI integration also facilitates predictive maintenance, where robots can monitor their own health and alert you to potential issues before a breakdown occurs. This proactive approach minimizes unexpected downtime, keeping your production lines running smoothly and efficiently.

You’ll also find that collaborative robots, or cobots, are becoming more prevalent thanks to AI integration. These robots work alongside human operators, assisting with tasks that require a blend of precision and judgment. Thanks to AI, cobots can interpret gestures, understand speech commands, and adapt to human workflows seamlessly. This fosters a safer, more efficient environment where human skills are augmented rather than replaced, leading to increased overall productivity.

In essence, the combination of robotic automation and AI integration is revolutionizing manufacturing by making robots smarter, more versatile, and more capable of working alongside humans. It empowers you to streamline operations, improve quality, and respond swiftly to changing production needs. As this technology continues to advance, you’ll find that embracing AI-enhanced robotics isn’t just an option—it’s a necessity to stay competitive in today’s fast-paced industrial landscape.

Frequently Asked Questions

How Do AI Robots Adapt to New Manufacturing Tasks?

You program AI robots with machine learning algorithms that enable them to adapt to new manufacturing tasks quickly. When faced with a new challenge, they analyze data and learn from previous experiences, increasing their task flexibility. This allows you to deploy them on a variety of tasks without extensive reprogramming. Over time, they improve their efficiency and accuracy, making your manufacturing process more agile and responsive to changing demands.

What Are the Safety Concerns With Ai-Enhanced Robotics?

You should be aware that safety concerns with AI-enhanced robotics include ethical considerations and liability issues. These robots can pose risks if they malfunction or make unpredictable decisions, potentially harming workers or damaging products. Ensuring proper safety protocols and clear liability guidelines helps prevent accidents. You need to monitor these systems continually, implement safety measures, and address ethical concerns proactively to maintain a secure and responsible manufacturing environment.

How Do AI Robots Impact Factory Employment Levels?

You might worry that AI robots will dramatically cut factory jobs, but the impact isn’t straightforward. While workforce displacement occurs as automation takes over routine tasks, it also pushes you to focus on skill development for higher-value roles. This shift can lead to more specialized employment opportunities. Embrace the change, and you’ll find that AI-enhanced robotics can transform your factory into a more innovative and resilient workplace.

What Maintenance Challenges Are Unique to Ai-Enabled Robots?

You might face unique maintenance challenges with AI-enabled robots, especially related to predictive diagnostics and hardware integration. Predictive diagnostics require continuous data analysis to foresee failures, which can be complex to establish and interpret. Hardware integration may also be tricky, as you need to guarantee seamless communication between AI systems and existing machinery, preventing compatibility issues that could lead to downtime or costly repairs. Proper planning minimizes these challenges and maximizes efficiency.

How Is Data Privacy Managed in Ai-Driven Manufacturing?

Imagine you’re in a sci-fi movie, but it’s real. You manage data privacy by implementing data encryption to protect sensitive information and access controls to restrict who can view or modify data. These measures ensure that AI-driven manufacturing data remains secure from cyber threats, safeguarding trade secrets and customer info while maintaining compliance. Staying proactive with encryption and access controls keeps your operations safe and trustworthy in this high-tech era.

Conclusion

So, next time your factory robot perfectly stacks boxes or sorts tiny screws, remember—you’re just witnessing the dawn of AI’s grand takeover. Soon, humans might be nothing more than nostalgic photos on the break room wall, reminiscing about the “good old days” of manual labor. Until then, sit back and enjoy the show as these AI-enhanced machines turn manufacturing into the ultimate sci-fi saga—starring your future robot overlords.